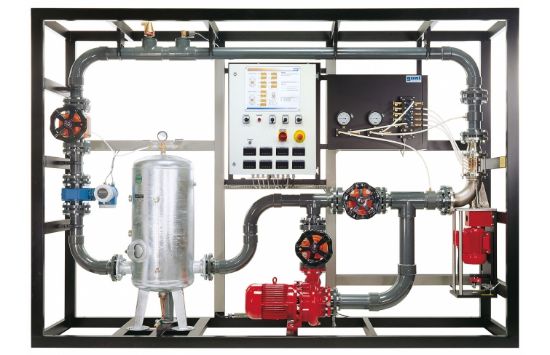

The GUNT Axial-Flow Turbomachine Demonstration Unit provides hands-on investigation of turbomachinery principles. Designed for educational use, the unit features a configurable axial turbomachine that can operate as either a pump or turbine. It includes multiple rotor and stator setups to demonstrate various blade and vane angles for comprehensive flow analysis.

Product Features

- Operates as both pump and turbine using interchangeable rotors and stators

- Includes four rotors and four stators with different blade and vane angles

- Closed water circuit with compressed-air powered expansion tank for water-free conversion

- Asynchronous motor acts as drive or generator depending on mode

- Transparent housing offers full view of rotor, stator, and flow processes

- 3-hole probe measures flow velocity and direction upstream, between, and downstream of components

- Supports analysis of velocity triangles for various blade/vane shapes

- Enables operation under different pressure levels for cavitation studies

- Inductive displacement sensor detects shaft speed contact-free

- Torque measured by force sensor on motor mounted on swivel bearings

- Manometers and pressure sensors record inlet/outlet and differential pressures

- Electromagnetic flow meter measures flow rate accurately

- All measurements displayed digitally for easy reading and analysis

Benefits

- Dual-mode functionality – Demonstrates axial turbomachinery as both a pump and a turbine

- Comprehensive flow study – Observe and measure flow characteristics across different rotor/stator configurations

- Highly visual – Transparent housing allows detailed examination of internal processes

- Tool-free configuration – Switch components without draining the system thanks to the pressurised expansion tank

- Accurate instrumentation – Sensors and digital displays provide real-time data for analysis

Why Choose the GUNT Axial-Flow Turbomachine Unit?

Ideal for fluid dynamics and turbomachinery education, the GUNT Axial-Flow Turbomachine Unit offers a flexible, instrumented platform for studying pump and turbine behaviour. With transparent visualization, real-time data, and multiple interchangeable components, it enables a deep understanding of velocity triangles, cavitation effects, and performance across various operating conditions.