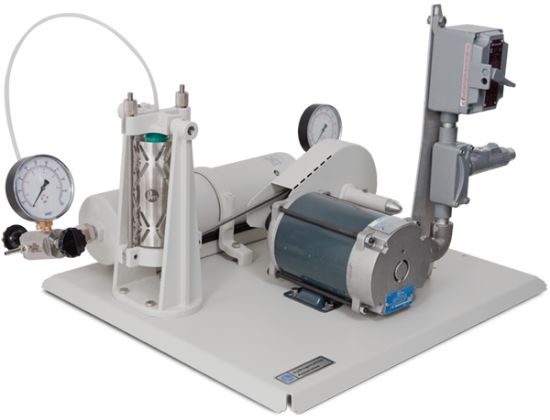

The Parr Hydrogenation APR Standard Motor apparatus provides a reliable system for treating chemicals with hydrogen in the presence of a catalyst at pressures up to 5 atmospheres (60 psig) and temperatures to 80°C. It is designed for synthesizing or modifying organic compounds by catalytic hydrogenation, reduction, or condensation, and is also suitable for any laboratory procedure involving vigorous mixing of liquid and gas in a glass reactor at low pressure.

Product Features

- Basic apparatus without heating mantle and temperature controller; option to add heating mantle and 4833 Temperature Controller

- Includes two extra 500 mL reaction bottles, twelve spare bottle stoppers, and six-foot pressure hose for filling the hydrogen tank

- Seals materials in reaction bottle connected to hydrogen reservoir; air removal by evacuation or hydrogen flushing

- Bottle shaking mechanism initiates reaction; bottles can be heated or cooled as necessary

- Progress monitored via pressure drop; calibration possible with known hydrogen acceptance compounds

- Convenient valves and fittings for admitting hydrogen, evacuating bottle, and filling tank without disturbing connection

- Separate pressure gauges for bottle and tank pressures

- Compact steel base assembly for bench or hood operation

- Polypropylene tubing gas connection avoids metal contact with charge

- Stainless steel tank, valves, and gauges suitable for hydrogen use

- Stainless stems, PTFE packing, and replaceable PCTFE seats ensure leak-proof control

- Available smaller 1-liter stainless tank option for semimicro operations

- Six-foot pressure hose for filling from commercial gas cylinders included

Benefits

- Reliable and safe system for low-pressure hydrogenation with precise control

- Flexible configuration with options for heating and temperature control

- Robust design minimizes contamination risk and ensures leak-proof operation

- Easy monitoring of reaction progress through pressure drop observation

- Compact, space-saving design suitable for laboratory benches or fume hoods

Why Choose Parr Hydrogenation APR?

Parr Hydrogenation APR systems are trusted worldwide for their proven reliability, safety features, and ease of operation. Their thoughtful design with high-quality components ensures consistent results and minimizes risks in catalytic hydrogenation procedures, making them ideal for teaching, research, product development, and pharmaceutical applications.