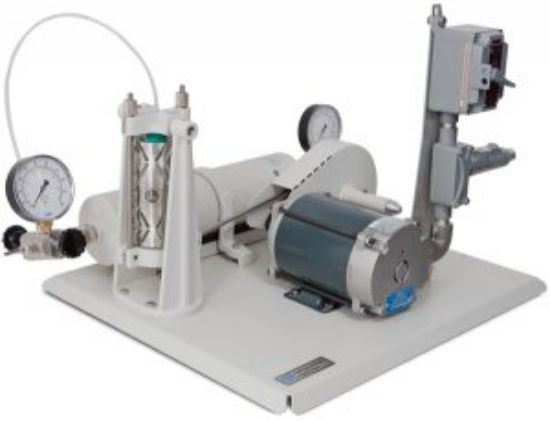

Parr shaker type hydrogenators provide compact and easily operated systems for treating chemicals with hydrogen in the presence of a catalyst at pressures up to 5 atmospheres (60 psig) and temperatures to 80°C. They are used primarily for synthesizing or modifying organic compounds by catalytic hydrogenation, reduction, or condensation. They are equally suitable for any laboratory procedure in which a liquid and gas must be mixed vigorously in a glass reactor at pressures up to 5 atm.

Product Features

- The 3910 Series Apparatus can be ordered under two configurations: basic apparatus without heating mantle and temperature controller, or with heating mantle and a temperature controller added.

- Includes two extra 500 mL reaction bottles, twelve spare bottle stoppers, and a six-foot pressure hose for filling the hydrogen tank.

- Equipped with an explosion-proof motor for enhanced safety in hazardous environments.

- Materials to be treated are sealed in a reaction bottle with catalyst connected to a hydrogen reservoir.

- Air is removed by evacuation or flushing with hydrogen before applying pressure from the reservoir.

- Bottle is shaken vigorously to initiate reaction, with heating or cooling as required.

- Pressure drop monitoring allows progress tracking of the hydrogenation reaction.

- Complete valves and fittings system enables hydrogen admission, evacuation, and tank filling without disturbing connections.

- Pressure gages continuously display bottle and tank pressures.

- Polypropylene tubing connects hydrogen tank to reactor to avoid metal contact with the charge.

- Stainless steel tanks and valves ensure durability and safety with hydrogen.

- Six-foot pressure hose included for easy connection to commercial gas cylinders.

Benefits

- Safe operation ensured by explosion-proof motor designed for hazardous atmospheres.

- Compact and user-friendly design optimizes lab bench space and workflow.

- Complete system with all necessary components for immediate use and reliable performance.

- Precise temperature control and monitoring for consistent reaction outcomes.

- Durable construction supports long-term use under demanding conditions.

Why Choose Parr Hydrogenation Apparatus?

Parr Hydrogenation Apparatus combines proven design with modern safety and control features to deliver reliable, efficient hydrogenation performance. Its robust construction, easy operation, and comprehensive features make it the preferred choice for laboratories requiring consistent results and safe handling of catalytic hydrogenation reactions.