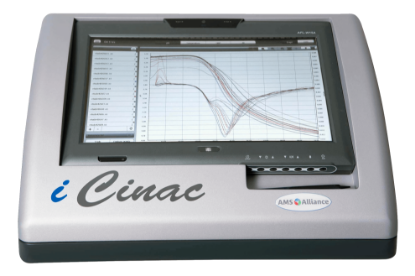

The AMS iCinac System Acid Monitor is a precise and high-performance solution designed to analyze lactic acid bacteria (L.A.B.) fermentation kinetics and control fermentation reactors. With 16-channel capability, it enables simultaneous acidification monitoring across multiple samples—ideal for research, product development, and quality control in dairy and fermentation labs.

Product Features

- 16-channel acidification monitoring for parallel sample analysis

- Designed specifically for L.A.B. fermentation kinetics and acidification studies

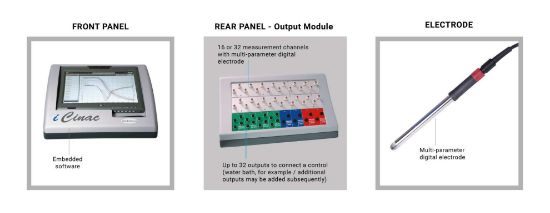

- Simultaneous monitoring of pH, temperature, and ORP using ISM protocol digital electrodes

- Scalable system: up to 32 wired or 16 wireless channels with independent electrode control

- Wired/wireless configuration options for flexible lab integration

- Easy-to-use software with real-time automatic configuration and module detection

- Compatible with ISO 26323 | IDF 213 dairy culture standards

How it Works

Lactic Acid Bacteria

Lactic Acid Bacteria (L.A.B.)’s main function is to produce Lactic Acid. Additionally, L.A.B. contributes to the flavor, texture, and nutritional value of fermented foods through production of aroma components. L.A.B. is also used as adjunct cultures, production or degradation of exopolysaccharides, lipids and proteins, production of nutritional components such as vitamins, and used as functional cultures. L.A.B. promotes therapeutic effects and is used for probiotics. In addition, L.A.B. contributes to the inhibition of spoilage and pathogenic microorganisms and thus, is used as bio-protective cultures.

iCinac Operation

The iCinac, when used as a L.A.B. activity and kinetics monitoring system, works by measuring pH and temperature in each reactor cell and this is represented as a pH vs. time, Temperature vs. Time, and ORP vs. Time series of graphs.

Users can then:

- Compare the curve (kinetics) to their defined Gold Standard or specific kinetics to see if the tested batch behaves as expected – e.g. as a quality control step, in compliance with ISO26323,

- Analyze new ferment strains kinetics and behavior under specific conditions,

- Develop inter comparison studies between batches, strains, external conditions, and more.

The iCinac, when used as a Fermentation L.A.B. bioreactor controller, not only monitors and records pH, Temperature and ORP (optional) in each reactor, but it also controls external systems through digital and analog outputs, such as peristaltic pumps, heating circulators, and others based on time and pH values. This allows the user to have a reactor that follows not only specific temperature-based programs, but also have automated adjustment of pH values as per the pre-programmed pH kinetics.

It ensures specific kinetics and behaviors are followed within each reactor, hence converting iCinac into a laboratory and pilot scale multi-bioreactor platform with complete monitoring, recording and control of external systems.

Experiments can be easily set up for iCinac wired:

- Turn on the iCinac

- Connect all required cables and electrodes

- Perform the calibration of all electrodes (pH calibration should be run before each experiment as per the defined protocol)

- Insert the electrode in the dedicated bioreactor and adjust the bioreactor conditions

- Start the iCinac experiment and initiate to obtain real-time data via the built-in PC

- Analyze your data at the end of the experiment

Benefits

- Enhances throughput with multi-channel simultaneous sample analysis

- Delivers accurate, reproducible fermentation data in compliance with ISO standards

- Reduces development time with reactor-scale control and modular design

- Improves quality control and consistency in L.A.B. acidification activity

- Customizable configuration with the option to scale up or modify channels and electrodes

- Controls heating baths, pumps, and circulators when paired with external control module

Why Choose the AMS iCinac System Acid Monitor?

The AMS iCinac Series is the industry-standard solution for monitoring and controlling lactic acid fermentation. It allows laboratories to find the most efficient starters, ensure batch consistency, and characterize acid formation across bacterial phyla. With flexible configurations and digital electrode compatibility, the iCinac platform supports advanced research, product development, and process optimization across multiple sectors.